Oil Skimmer

OIL SKIMMER

An oil skimmer is a machine that removes floating oil and grease from liquid. The floating oil adheres to skimming media, such as a belt, tube, rope, mop, or disk. The media then runs back to the machine to be wiped clean. Weir style skimmers use a pump to collect floating oils.

An oil skimmer is a device that is designed to remove oil floating on a liquid surface from oil spills. The effectiveness of a skimmer is highly dependent on the roughness of the surrounding water that it is working on, the more choppy the surrounding wake and water the more water the oil skimmer will take in rather than just oil. Skimmers are either self propelled, used from shore or operated from vessels depending on the oil spill scenario.[1] Depending on these specific designs they are used for a variety of applications other than oil spills such as a part of oily water treatment systems, removing oil from machine tool coolant and aqueous parts washers, and collecting fats oils and greases in wastewater treatment in food manufacturing industries.

Oil skimmers were used to great effect to assist in the remediation of the Exxon Valdez spill in 1989. Oil skimmers are different from swimming pool sanitation skimmers that are designed for a related but same purpose.

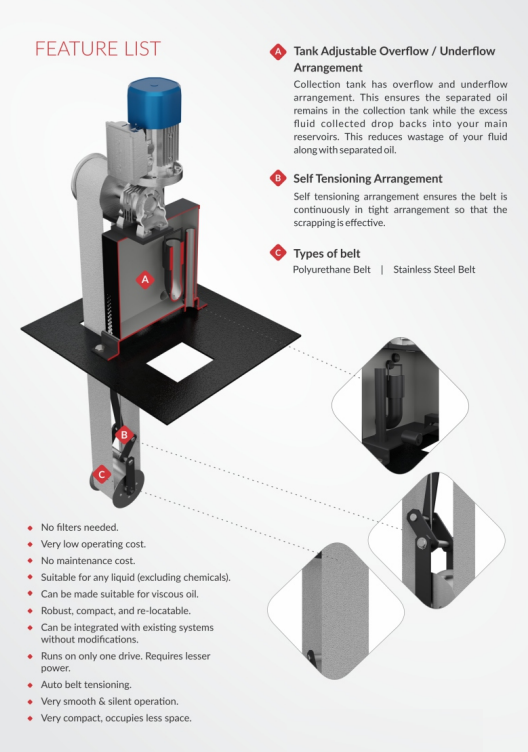

AOS SERIES

OIL SKIMMER SYSTEM

- Product Design

- Special Features

There are many different types of oil skimmer. Each type has different design features and therefore results in different applications and use. It is important to understand the design features before employing a particular skimmer type.

Some factors to consider are:

- Oil removal flow rate: Alternative Skimmer designs have different oil removal flow rates. Volume removal rates for Oleophilic skimmer types (drum, brush, disc, belt) are comparatively low. Weir type skimmers are capable of very high oil and water removal rates. ASTM F2709 standard establishes the test procedure for determining oil recovery rate (ORR).

- Oil removal concentration: It is a common misconception that oil skimmers remove concentrated or pure 'oil'; when in fact they remove a mixture of oil and water. In most situations the 'oil' mixture removed is an emulsion of oil and water more like a 'mousse'. Oleophilic and Non-Oleophilic skimmers can provide a more concentrated oil in the removal stream, however still collect entrained water.

- Effectiveness with different oils: Oleophilic and Non-Oleophilic skimmers are not equally effective with all oil types due to the changing nature of the attraction forces with different oils and materials.

- Effectiveness with chemicals in the water: Oleophilic skimmers may not work as effectively if there are detergents, cleaners or other surfactants in the water that interfere with the oleophilic attraction. Weir skimmers are not affected by chemicals.

- Effects of trash and debris: Trash and debris may block or interfere with the operation of oil skimmers.

- Skimming direction: Some skimmers only remove oil from one direction. In some situations, such as skimming from pits and tanks, it can be important to remove oil from all directions.

- Service Access: Some skimmers such as disc skimmers, or weir skimmers with skimmer mounted pumps, contain heavy serviceable items of equipment mounted on the skimmer. This may require special lifting equipment and confined space entry safety considerations before servicing.

OIL SKIMMER SYSTEM

Product Description:

In order to keep pace with never ending demands of customers, our company provides supreme quality range of Oil Skimmer. Our product range including Oil Skimmer is checked under various set norms of the industry. To attain the maximum satisfaction of customers, we provide this product at pocket-friendly price.

Features:

- Best grade material

- High performance

- Superb efficiency

Waste Water or ETP Application (Oil Removal Rate) Belt Oil Skimmer : Belt Width 65mm (20-27 LPH) Belt Width 100mm ( 55-65 LPH) Belt Width 200mm (95-110 LPH) Double Belt type high oil removal rate Oil skimmer (210-320LPH)

| Minimum Order Quantity | 1 Piece |

| Capacity | 5 LPH TO 320 LPH |

| Brand | AMIKON |

| Model | AOS-OIL SK1010 |

| Oil Recycle Rate | 200 (l/hr), 10 (l/hr), 50 (l/hr), 1000 (l/hr) |

| Width of Belt | UPTO 300, 80 mm, 90 mm |

| Number of belts | 1, 2 |

| Length of Belt | 1000 mm, 1200 mm, 1400 mm |

| Usage/Application | OIL SEPERATION |

| Depth of tank | 140 mm, 100 mm |

| Motor Rating | 05 HP, 1.0 HP, 1.5 HP, 2.0 HP ETC |

| Size of belt | 100 to 450 mm |

| type | Vertical |

Products Range :

- Belt Oil Skimmer : Belt Width 65mm (20-27 LPH) Belt Width 100mm ( 55-65 LPH) Belt Width 200mm

- Motor Rating : 05 HP, 1.0 HP, 1.5 HP, 2.0 HP ETC

- Capacity : 5 LPH TO 320 LPH