Screw Pumps

PROGRESSIVE CAVITY SCREW PUMPS

We are the supplier of screw pump for sewage dewatering and sludge dewatering with the capacity range of 0.15 m3/hr to 200 m3/hr in single stage upto max pressure 36Kg/cm2.

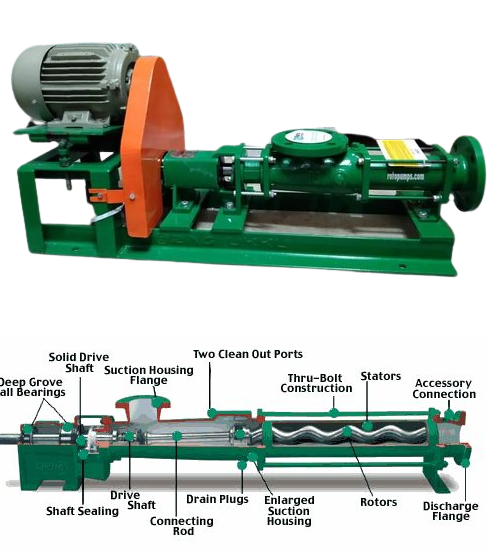

The main pumping elements of Progressive Cavity Pump are single external helix metallic Rotary part Rotor and a fixed double internal helix polymer part Stator. As the rotor rotates within the stator, the cavities progress from suction to discharge end of the progressive cavity pump carrying the fluid.

The pumping element comprises of a precision machined single external helix metallic rotor, and a double internal helix elastomer stator. Due to the special profile of the rotor and stator set, a sealing line is formed along the axis of the rotor which is maintained at both static and dynamic conditions.

As the rotor turns within the stator, these cavities progress from the suction to the discharge end of the pump carrying the fluid.

APSP SERIES

- Product Design

- Special Features

Progressive cavity pumps also known as positive displacement pumps or screw pumps, are used to pump heavy, abrasive and low to high viscous fluids like molasses, magma, syrup, Spentwash, potato pulp, cement slurry, mine water, effluent treated waste etc. These are heavy duty pumps working on the principle of Rotary positive displacement system.

The pumping element comprises of a precision machined single external helix metallic rotor, and a double internal helix elastomer stator. Due to the special profile of the rotor and stator set, a sealing line is formed along the axis of the rotor which is maintained at both static and dynamic conditions.

As the rotor turns within the stator, these cavities progress from the suction to the discharge end of the pump carrying the fluid.

Products Range :

- Capacity Upto 200 M3/Hr.

- Head Pressure Upto 45 Mtr./ Bar

- Percentage of solids handled- up to 60%

WORKING PRINCIPLE

We are one of the leading manufacturers and exporters of single screw type progressive cavity pumps. The main component in this pumps is a metal single-threaded rotor which rotates around its principal axis and around the axis of the stator section producing cavities at reduced pressures which move axially from inlet to outlet conveying the fluid at fixed flow rate proportional to the rotational speed.

The pumping element comprises of a precision machined single external helix metallic rotor, and a double internal helix elastomer stator. Due to the special profile of the rotor and stator set, a sealing line is formed along the axis of the rotor which is maintained at both static and dynamic conditions.

As the rotor turns within the stator, these cavities progress from the suction to the discharge end of the pump carrying the fluid.